Features of the SVM-6151IP:

Bubble-Free Coatings: Advanced alignment and vacuum coating ensure smooth, defect-free coatings, ideal for electronics, semiconductors, and optics

Versatile Printing: Perfect for a variety of tasks like selective printing, semiconductor filling, and high-aspect ratio plugging, suited for industries like automotive, medical, and packaging

Optimized Efficiency: Adjustable speed (10 to 300 mm/sec) and pressure (100-800 N) settings allow for smooth, customized workflows; the screen-less design reduces downtime and ink issues.

Reliable Quality: Consistent, high-quality coatings for delicate components in electronics, semiconductors, and decorative parts

Auto Alignment System: Automatically aligns components precisely, reducing human error and ensuring top-quality results

High-Precision Coating: Achieves precise coatings with vacuum pressures from 100–12,000 Pa, providing consistent results for demanding industries

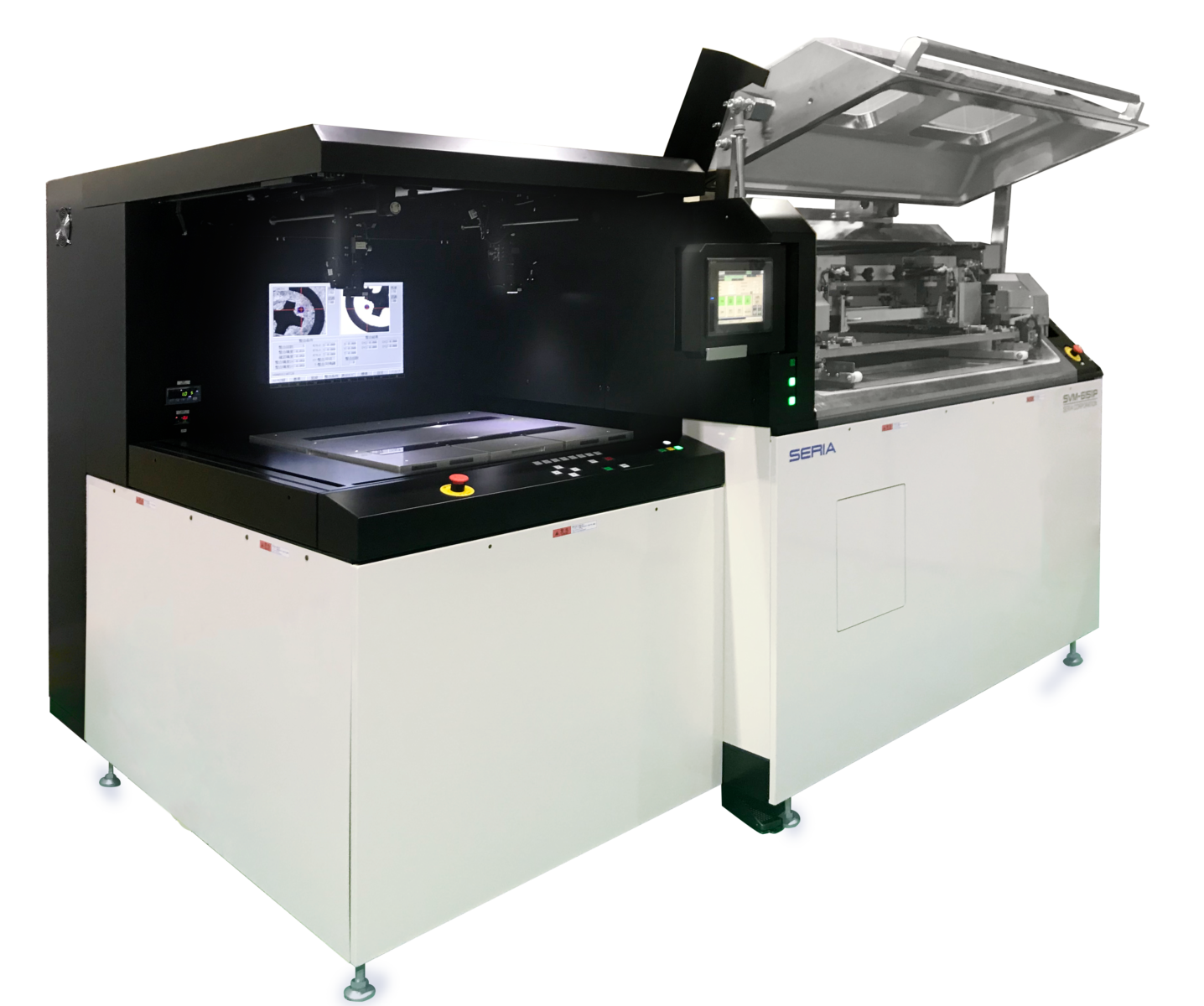

Features of the SSA-DSV650:

Space-Saving Vertical Design: Compact layout ideal for limited spaces

Double-Side Printing: High-precision, uniform resist application on both sides of PCBs

Flexible Shuttle Options: Choose between single or dual shuttle configurations for different production needs

Cost-Effective Solder Mask Use: Minimizes material waste, reducing costs

Fast Color Change: Quick and easy color changes for improved production efficiency

Back Squeegee Function: Controls printing pressure and cleans the rear side of the screen for consistent quality

Automatic Performance Adjustments: Self-adjusting parameters for consistent quality with minimal manual input

Seamless Automation Integration: Easily integrates into automated production lines

Precision Control: Adjustable squeegee speed (25–250 mm/sec) and angle (±30°) for accurate printing

Reliable Seria Technology: Built on Seria’s trusted screen-printing expertise for dependable performance

Versatile Size Support: Accommodates work sizes from 250×250 mm to 650×650 mm

Features of the SSA- PC660 & PC660IP & PC760IP

High-Quality Printing: Delivers exceptional print

quality for high-density electronicsUser-Friendly Operation: Semi-automatic design with

simple controls for efficient printingWide Material Compatibility: Handles both thin and

thick materials, offering flexibilityPrecise Vertical Movement: Table vertical slide system

ensures accurate printingStable Positioning: Magnet chuck table positioning for

consistent resultsQuiet and Accurate: Servo mechanism improves

accuracy and reduces noiseEasy Parameter Adjustments: Touch panel for quick,

simple parameter settingsUltra-Fine Printing: Capable of printing ultra-fine

patterns for advanced electronicsCustomizable Features: Available in different models

with tailored features based on customer needs, including

optional CCD camera for improved alignment and

precision

Features of the PEPIO F6/F15

Applications: Ideal for semiconductor manufacturing, microelectronics, flexible circuits, fine-line packaging, and ball/solder ball mounting

High Precision: 5 µm line width, φ5 µm dot diameter, ±5 µm accuracy for high-resolution printing

Versatile Use: Perfect for ball mounting, flexible circuits, and fine-line packaging in semiconductors, microelectronics, and other high-tech industries

Speed Options: Adjustable speeds from 2 mm/s to 200 mm/s for both fast and detailed printing

Stable Alignment: Dual CCD cameras and vacuum system ensure precise registration and stable positioning

Efficient Setup: Automatic zero-point setting reduces downtime and manual adjustments

Ink and Blanket Management: Integrated ink dispenser and blanket cleaner for consistent printing

Semiconductor Focus: Great for 30 µm ball mounting technology

Precise Speed Control: Adjustable speed down to 0.1 mm/s for accurate prints

Clean Printing: Anti-static bars, blanket dryer, and full-frame cover maintain cleanliness

Features of the RYURONE 35SZ

Gapless Synchronized Printing: World’s first gap 0 (cylinder synchronous type) for precision and repeatability

High Resolution: Screen peel-off mechanism ensures uniformity and high resolution, ideal for MLCC and electronic components

Accurate and Stable: Stress-free screen mechanism provides excellent accuracy and stability

Reduced Defects: Stable peel-off minimizes bleeding, improving print quality

Non-Touch Loading: Prevents component damage, maintaining quality. · Versatile Compatibility: Works with films and green sheets, widths from 250–350 mm, thicknesses from 25–100 µm

Flexible Speed Control: Adjustable printing and coating speeds from 50–800 mm/sec

Efficient Unwinding/Winding: 3-inch air shaft with max roll size of φ600 mm and 120 kg weight capacity

Features of the SFA-CP70IP

Compact Design: Space-efficient with high performance in a smaller footprint

IoT Monitoring (Optional): Enables remote production oversight for streamlined operations

Quick Setup: Fast setup reduces downtime and improves workflow efficiency

AI-Ready: Prepared for future AI integration for long-term relevance. · Global Safety Compliance: Meets international safety standards for secure operation

Load Cell Monitoring: Ensures consistent print pressure for high-quality results

Auto 0 Point Setting: Automatic squeegee and scraper positioning for precise alignment

CCD Camera Alignment: Auto-registration and precise chip placement with image processor-based CCD camera

Safety Features: Aluminum frame with safety cover, door interlock, and switch for operator protection

Customizable Features: Different models available with tailored features to meet customer needs

Hand Print Unit

Features:

Although this is a hand print unit but corresponding to precision printing and various type of substrate printing

Table section vacuum unit (OP)

Clearance adjustment function

Table alignment by micro meter