Features:

Original orbital 10 brush post via fill planarizer with original Pola & Massa orbital brush technology

Upgraded design based on more than 100 units sold since 2004

High sanding power with 10 brushes translates into productivity

Quick release brushes

Panel edges can be selectively sanded “picture frame mode”

Thin material guide system

User friendly gravity filter system

Optional anti-warp system for thin material

Features:

Single brush automatic conveyorized sander

Programmed recipes can be set up for different sanding requirements

Regional sanding, such as only panel perimeter or center or distinct areas

Various sanding media diameters are available

xxxx

Features:

Designed for cleaning PCBs after routing, prior to packaging, post final finish

Equipment is provided optionally with top and bottom Nylon brushes

Heating of 1st rinse sump and surfactant addition is possible

Multiple rinse zones with high pressure pump options

Fluid head drying; 2 pairs of heads being standard

Full stainless steel machine with painted steel covers

Features:

Stainless steel made, the machines are suitable for copper surface preparation before dry-film application or other printing processes;

Metal surface, also thanks to the support of dedicated brushes, is perfectly cleaned getting a proper roughness to facilitate a better dry-film adherence;

Machines can alternatively use pumice or aluminum oxide;

xxx

Features:

For cleaning of PCBs after HASL or IR Reflow

Cleaning after any processes that contaminate the PCB

Warm water brushing and high pressure rinsing

Nylon brushes assist the cleaning process

Fluid head drying; 2 pairs of heads being standard

Full stainless steel machine with painted steel covers

Features:

Used for deburring after drilling or pressplate cleaning

Also used for pretreatment process solutions

Single frame machine with full stainless steel body with painted steel covers

Thin board capability to 4 mil cores

Automatic thickness adjustment for consistent footprint

Recipe set-up for different panel designs

2 or 4 brush version available

With optional Copper particle filter

Optional pre-scrub blow-off module

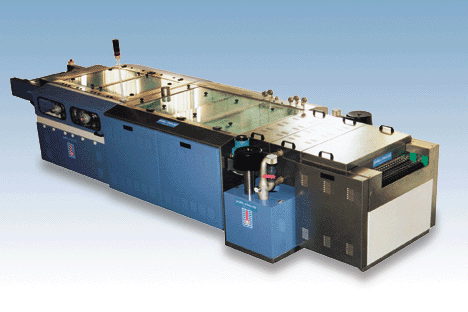

Features:

Used for deburring after drilling or pressplate cleaning

Also used for pretreatment process solutions

Modular machine with full stainless steel body with painted steel covers

Machine design allows inclusion of ultrasonic, super high pressure or super high flow rinse modules

Thin board capability to 4 mil cores

Automatic thickness adjustment for consistent footprint

Recipe set-up for different panel designs

2 or 4 brush version available

With optional Copper particle filter

Optional pre-scrub blow-off module

Features:

For loading and unloading rigid and semi rigid boards where the boards must not touch each other

The boards are held in slot-racks in semivertical position separated from each other to prevent scratches and deformation

The rack is conveniently moved to/from its trolley for easy handling in the factory.

The unloader unit is fitted with a centering de

Features:

For loading and unloading rigid and semi rigid boards where the boards must not touch each other

The boards are held in slot-racks in a semi-vertical position separated from each other to prevent scratches and deformation

The rack is conveniently moved to/from its trolley for easy handling in the factory.

The unloader unit is fitted with a centering device