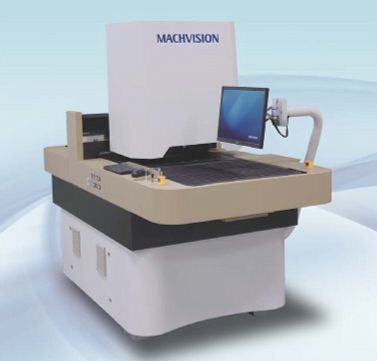

Machvision was stablished in 1998 to serve as a supplier of professional optical inspection equipment (AOI). The main products include: inspection of PCB inner and outerlayers as well as drill patterns, finished, solder masked circuits, laser microvias, HDL and IC applications. The company deploys advanced technologies related to optical imaging, image processing, precision machinery and motion control. Besides standard manual load and unload units, Machvision offers state of the art conveyorized, inline innerlayer inspection systems that can be integrated inline with DES, punch or oxide lines. Machvision has quickly gained a strong position in the field of AOI for PCB applications, due to it’s very large focus on R&D and innovation.