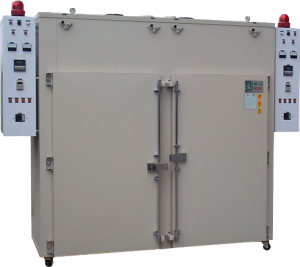

Single and Double Chambers Ovens

Features:

Various types of carts and racks available

Single and double chamber ovens available in various sizes

Trolley rack loading or shelves

Various programming levels available for multi-step processes

Double over temperature protection

Trolley type, N2 Purge type, steam type available

Assembly and cleaning in clean room for clean oven

UV Curing Machine

Features:

Metal halide and mercury UV lamp available

Strong UV penetration

High UV intensity

Fast curing

Single and double sided unit available

Dual and single UV lamp units based on productivity needs

Vacuum Chamber

Features:

For degassing and debubbling applications

Various sizes available

IR Convection Heat Conveyorized Ovens

Applications and Features:

Solder mask drying

Marking cure

Silver paste drying

Pre-baking before lamination

Carbon pattern drying

Roll to roll drying

Variable length available & divided into separate heating zones

Various types of conveyorized convection ovens available

Wide range of conveyorized ovens

Features:

Hang ovens for thin materials

Frame ovens for material as thin as 50 microns total thickness

Rack tunnel ovens with entrance and exit doors for improved temperature control

Wicket ovens

Applications include:

Solder mask drying and curing

Oxide innerlayer baking prior to lamination

Roll to Roll Process Equipment

Winders & Unwinders with full process line integration

Dry film lamination

Including:

Winders & Unwinders

Dryfilm lamination

Exposure

Lamination

Curing & Baking