Advantages of the MSC systems

Very high precision, i.e. also suitable for laser drilling

The microsection is standardized and can be executed quickly even by semiskilled personnel

High throughput volume is possible; a single person can process > 100 specimens/layers

Significant reduction of material consumption (sand paper, resin, etc.)

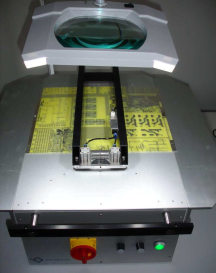

1) Precise milling machine with digital video camera system which prepares the coupon(S-OSR)

Easy handling with touch screen and computer mouse

High flexibility through parameter set up

Desktop design fits everywhere in your lab and process environment

All FR4 type and other base materials processable, also with heavy Copper Aluminum carrier

Maximum processable PCB thickness around 6 mm

Standard cutter: 2.4 (Shaft 3.175; spiral length 6-8 mm)

Coupon size: standard 21×10, maximum 30×14 mm

Additional holes in the coupon possible

Workflow:

Defining the exact coupon location and cross section target area using the video camera

Milling the coupon from the circuit board

Inserting the coupons into specimen holders (pucks); no need for pinsFilling with casting resin

Fully automatic sanding and polishing to the center of the target holes with the SPA

Multifunctional desktop coupon router (OSR)

Features:

The OSR is a very flexible and handy milling machine for extracting coupons from printed circuit boards

All kind of base materials can be processed up to a thickness of 6 mm