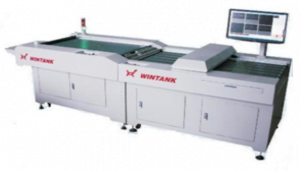

Wintank was founded in 2006. Starting with the conveyorized hole checking equipment, various additional products have been introduced over the years since the company was started. These include in 2011 the drilling quality analysis equipment which has been significantly upgraded in 2015 with many other features as well as panel flatness testing equipment. Over the past ten years Wintank has made continuous progress and growth because we understand that in this highly competitive society, only continuous growth is the only law of survival.