Features:

Processes available for both alkaline and cupric etching

Solvent extraction method of the Copper and subsequent Copper electro-winning

No replenisher needed for the alkaline process

Oxygen regeneration of the cupric etchant; no dangerous, toxic oxidation processes needed

Excellent etching process control due to continuous feed of fresh etchant

Copper being removed from rinse water as well –water consumption saving

No replenisher etchant needed

Cu slabs 99.9% pure are generated – sold at market price

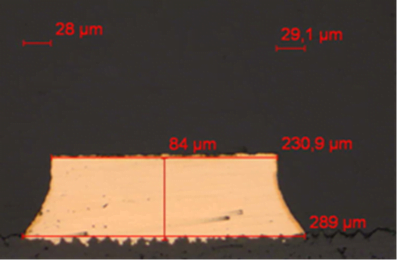

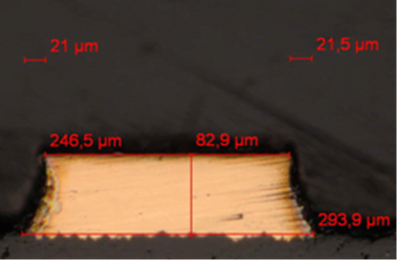

Cross sections below show how the etching results are improved when using an Oxidation Reactor system