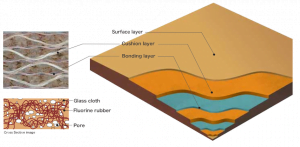

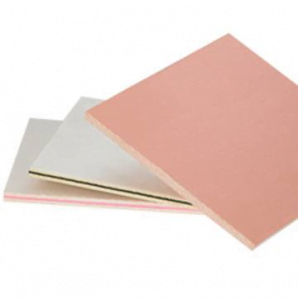

Yamauchi has a long history for producing a wide range of quality products over the years. Press pads are vital to circuit board manufacturing and can mean the difference between good quality boards and those that aren’t acceptable by the end user.However, these pads become costly, being used once and tossed, creating large amounts of waste, inventory, and problems. Reusable press pads from Yamauchi solve those issues while providing excellent quality and cost. These pads are ideal for pin-less lamination systems, but may be used with pin-lam as well depending on conditions and needs.